Products

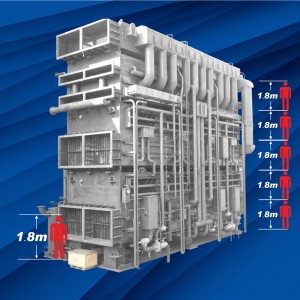

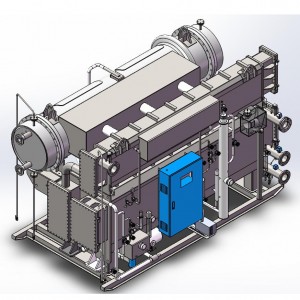

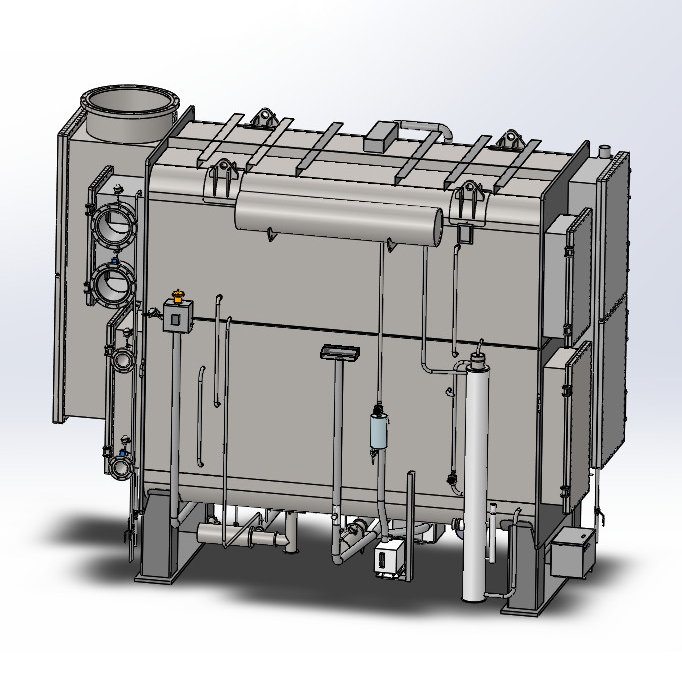

Kirasi II Absorption Heat Pump

Kushanda Nheyo

Kazhinji, Kirasi II absorption yekupisa pombi imwe yemhando yeLT tsvina inofambiswa nemhepo, iyo inotora kupisa kubva mumarara mvura inopisa kuti ibudise mvura inopisa ine tembiricha yepamusoro pane inofambiswa tsvina inopisa mvura.Iyo inonyanya kutaridzika yemhando iyi yekupisa pombi ndeyekuti inogona kuburitsa mvura inopisa ine tembiricha yepamusoro pane kutambisa mvura inopisa pasina mamwe maturusi ekupisa.Mumamiriro ezvinhu aya, tsvina inopisa mvura ndiyowo inopisa.Ichi ndicho chikonzero Kirasi II yekunyudza kupisa pombi ichizivikanwa setembiricha inowedzera kupisa pombi.

Mvura inopisa inopisa inopinda jenareta uye evaporator munhevedzano kana nenzira yakafanana.Mvura yefiriji inotora kupisa kubva mumarara emvura inopisa muevaporator, yobva yabuda muhutsi hwefiriji uye inopinda mumudziyo.The concentrated solution in absorber inova diluted solution uye inobudisa kupisa mushure mekutora mupfunga wefiriji.Kupisa kunopisa kunopisa mvura inopisa kusvika kune inodiwa tembiricha.

Kune rumwe rutivi, mhinduro yakasvibiswa inopinda mujenareta mushure mekupisa kuchinjanisa neyakagadziriswa mhinduro kuburikidza nekupisa kupisa uye inodzokera kune jenareta, iyo inopiswa nemarara inopisa mvura uye yakanyungudutswa mune yakagadziriswa mhinduro, yozoendeswa kune absorber.Iyo refrigerant mhute inogadzirwa mujenareta ndeye

inounzwa kune condenser, uko inonamirwa mumvura nemvura yakadzika inotonhorera uye inounzwa

kuevaporator nepombi yefiriji.

Kudzokororwa kweiyi kutenderera kunosanganisira kuenderera mberi kwekudziya.

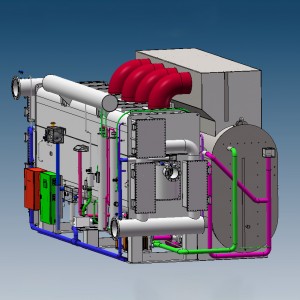

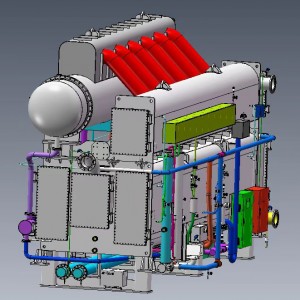

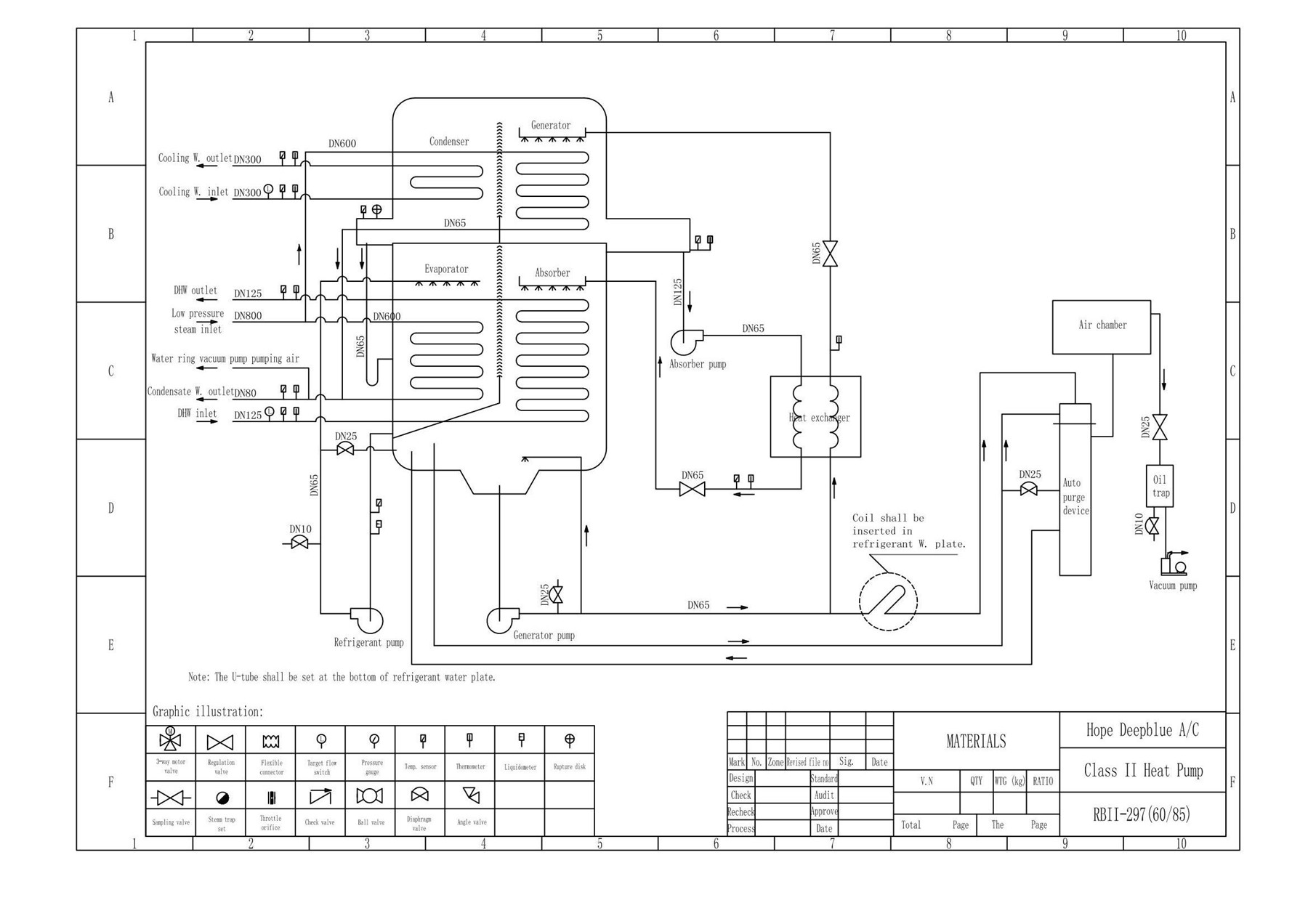

Maitiro ekuyerera Dhiagiramu

Zvikamu Zvikuru uye Mabasa

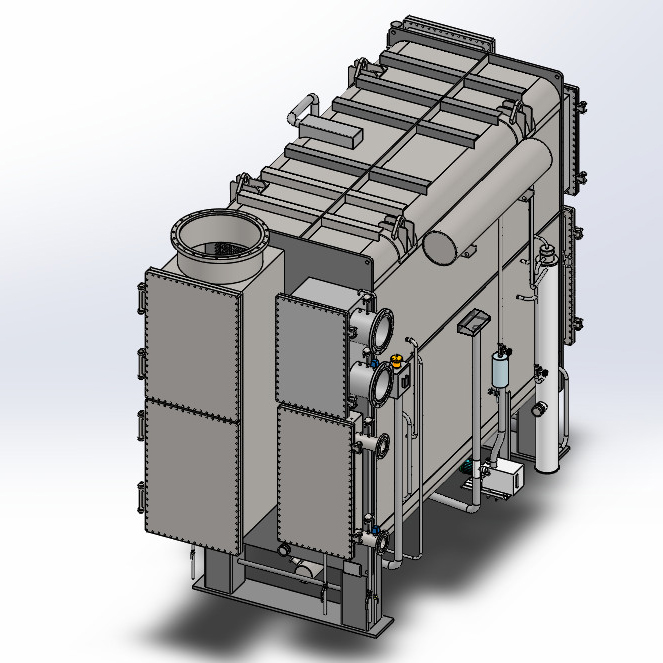

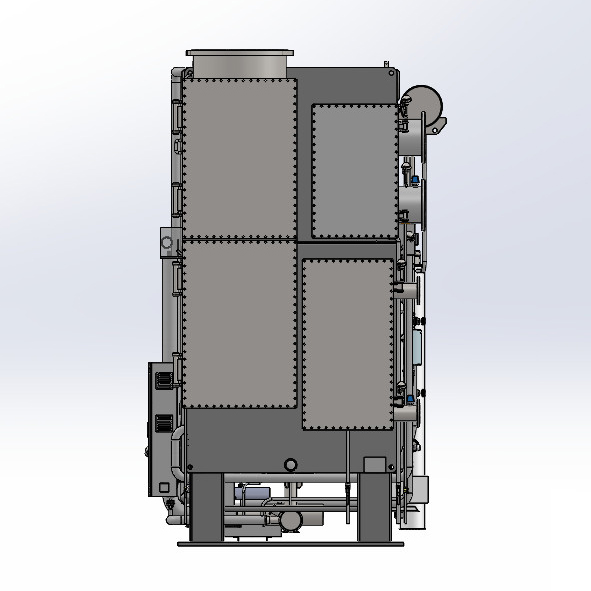

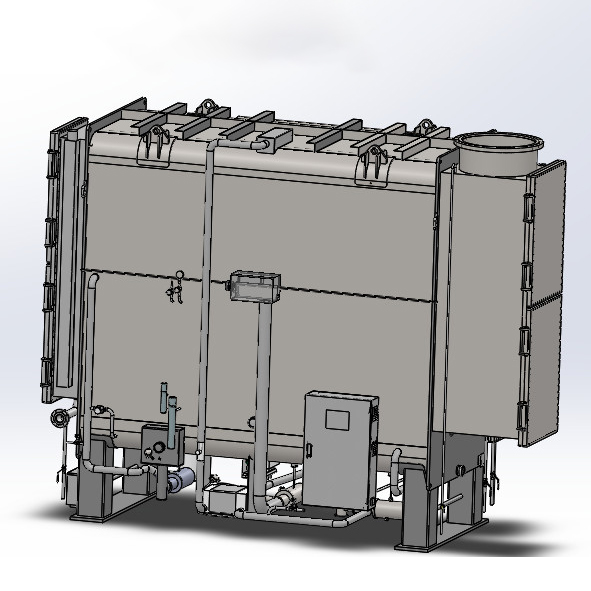

1.Jenareta

Basa reChizvarwa: Jenareta ndiro simba repombi yekupisa.Iyo Inotyairwa kupisa sosi inopinda mujenareta uye inopisa iyo yakanyungudutswa LiBr mhinduro.Mvura mumhinduro yakasvibiswa inoputika nenzira yefriji yefriji uye inopinda mu condenser.Zvichakadaro, iyo yakanyungudutswa mhinduro inoisa mune yakagadziriswa mhinduro.

Inoratidzira ganda-uye-tubhu chimiro, jenareta inosanganisira kupisa kwekutamisa chubhu, chubhu shiti, ndiro yekutsigira, goko, bhokisi remhepo, kamuri yemvura uye baffle ndiro.Semudziyo wepamusoro-soro mukati mepombi yekupisa, jenareta ine vacuum yemukati inosvika zero (micro negative-pressure).

2. Condenser

Basa reCondenser: Iyo condenser inhengo yekugadzira kupisa.refrigerant steam kubva mujenareta inopinda mucondenser uye inopisa DHW kusvika kune tembiricha yepamusoro.Zvadaro kupisa kwemhepo kunowanikwa.Mushure mekunge mutsi wefiriji wapisa DHW, inonyunguduka muchimiro chefiriji yemhepo uye inopinda muevaporator.

Inoratidzira ganda-uye-tubhu chimiro, iyo condenser inosanganisira kupisa kwekutamisa chubhu, chubhu shiti, ndiro yekutsigira, goko, tangi yekuchengetedza mvura uye kamuri yemvura.Kazhinji, condenser uye jenareta zvakabatanidzwa zvakananga nemapombi, saka ivo vane kunyanya kufanana kwakafanana.

3. Evaporator

Basa reEvaporator: Iyo evaporator itsvimbo inopisa yekudzoreredza unit.Mvura yefiriji kubva mucondenser inobuda pamusoro pechubhu yekutamisa kupisa, ichibvisa kupisa uye kutonhodza CHW mukati mechubhu.Nokudaro kupisa kwemarara kunodzorerwa.refrigerant steam inoputika kubva pamusoro pechubhu yekupisa inopisa inopinda mumudziyo.

Inoratidzira ganda-uye-chubhu chimiro, iyo evaporator inosanganisira kupisa kwekutamisa chubhu, chubhu shiti, tsigiro ndiro, goko, baffle plate, drip tray, sprinkler uye kamuri yemvura.Kumanikidza kwekushanda kweiyo evaporator kwakatenderedza 1/10 yemagetsi ejenareta.

4. Mubati

Basa reAbsorber: Iyo inopinza inhengo yekugadzira kupisa.Refrigerant steam kubva kune evaporator inopinda mumudziyo, iyo inobatwa neyakagadziriswa mhinduro.Mushonga wakadzikiswa unoshanduka kuita munyungurudzo wakanyungudutswa, unove pombi inounzwa muchikamu chinotevera.Nepo mupfunga wefiriji uri kunyudzwa nemushonga wakanyungudika, huwandu hukuru hwekupisa hunotorwa hunogadzirwa uye kupisa DHW kusvika kune tembiricha yepamusoro.Nokudaro kupisa kwemhepo kunowanikwa.

Inoratidzira ganda-uye-chubhu chimiro, chinopinza chinosanganisira kupisa kwekutamisa chubhu, chubhu shiti, ndiro yekutsigira, goko, pombi yekuchenesa, sprayer uye kamuri yemvura.Iyo inopinza ndiyo yakaderera-kudzvanywa mudziyo mukati mekupisa kwepombi system uye iri pasi pesimba rakakura kubva kumhepo isina-condensable.

5. Heat Exchanger

Heat Exchanger Basa: Iyo yekutsinhanisa kupisa itsvina yekudzosa kupisa unit inoshandiswa kudzoreredza kupisa muLiBr mhinduro.Kupisa mukugadzirisa kwakagadziriswa kunotamirwa neanopisa kupisa kusvika kune yakasvibiswa mhinduro yekuvandudzwa kwekushisa kwekushisa.

Inoratidzira chimiro cheplate, iyo yekupisa yekupisa ine yakakwirira yekupisa inoshanda uye inocherekedza simba rekuchengetedza simba.

6. Automatic Air Purge System

Basa reSystem: Iyo air purge system yakagadzirira kupomba kunze kwemhepo isina-condensable mupombi yekupisa uye kuchengetedza yakakwira vacuum mamiriro.Panguva yekushanda, iyo yakanyungudutswa mhinduro inoyerera pamwero wepamusoro kuburitsa nzvimbo yakaderera yekumanikidza yakatenderedza ejector nozzle.Nokudaro iyo isinga-condensable mhepo inoputirwa kunze kwepombi inopisa.Iyo sisitimu inoshanda panguva imwe chete nepombi yekupisa.Ipo pombi yekupisa iri kushanda, iyo otomatiki sisitimu inobatsira kuchengetedza yakakwira vacuum mukati uye ive nechokwadi chekuita kwehurongwa uye hupenyu hwesevhisi hwakanyanya.

Iyo air purge system isystem inoumbwa neiyo ejector, inotonhorera, mafuta musungo, silinda yemhepo uye vharafu.

7. Solution Pombi

Iyo pombi yemhinduro inoshandiswa kuendesa LiBr mhinduro uye kuchengetedza yakajairika kuyerera kwemvura inoshanda masvikiro mukati mepombi yekupisa.

Iyo pombi yemhinduro ipombi yakavharirwa-yakavharwa, yakakandwa centrifugal pombi ine zero fluid leakage, ruzha rushoma, kuputika-chiratidziro chepamusoro, kugadzirisa kushoma uye hupenyu hurefu hwesevhisi.

8. Refrigerant Pombi

Iyo pombi yefiriji inoshandiswa kuendesa mvura yefiriji uye kuve nechokwadi chekupfapfaidza kwakajairika kwemvura yefiriji pane evaporator.

Iyo pombi yefiriji ipombi yakavharirwa-yakavharwa, yakakandwa centrifugal pombi ine zero fluid leakage, yakaderera ruzha, yakakwirira kuputika-chiratidziro kuita, kushoma kugadzirisa uye hupenyu hurefu hwesevhisi.

9. Vacuum Pombi

Iyo pombi yevacuum inoshandiswa pakutsvaira padanho rekutanga uye kuchenesa mweya padanho rekuvhiya.

Iyo pombi yevacuum ine vhiri re rotary vane vhiri.Bhatani rekuita kwayo ndeye vacuum mafuta manejimendi.Kudzivirirwa kwemafuta emulsification kune mhedzisiro yakanaka pakuita kwekuchenesa mweya uye kunobatsira kurebesa hupenyu hwesevhisi.

10. Magetsi Cabinet

Senzvimbo yekudzora yekirasi II yekunyudza kupisa pombi, kabati yemagetsi inogara iyo huru yekutonga uye zvikamu zvemagetsi.

Waste Heat Recovery.Kuchengetedza Kwesimba & Kuderedza Kuburitsa

Inogona kuiswa kudzoreredza LT tsvina inopisa mvura kana LP chiutsi mumagetsi ekupisa, kuchera mafuta, petrochemical munda, simbi engineering, makemikari kugadzirisa munda, etc. Inogona kushandisa mvura yerwizi, pasi pevhu kana imwe yakasikwa mvura sosi, kushandura LT mvura inopisa. mumvura inopisa yeHT nechinangwa chekudziya kwedunhu kana kupisa.

Kirasi II Type ine Yakakwira Kupisa Kwemvura Tembiricha

Kirasi II yekunyudza kupisa pombi inogona kuvandudza tembiricha yemvura inopisa kusvika ku100 ° C pasina kumwe kupisa.

Dual effect (Inoshandiswa Kutonhodza/Kupisa)

Inotyairwa negasi rechisikigo kana chiutsi, mbiri mhedzisiro yekupinza kupisa pombi inogona kudzoreredza kupisa kwemarara nekunyanya kushanda nesimba (COP inogona kusvika 2.4).Iyo inoshongedzerwa nezvose zviri zviviri kupisa uye kutonhora basa, kunyanya inoshanda kune panguva imwe chete yekudziya / kutonhora kudiwa.

Maviri Phase Absorption & Yakakwira Tembiricha

Kirasi II chikamu chechipiri chekutora kupisa pombi inogona kuvandudza tembiricha yemvura inopisa kusvika ku80 ° C pasina kumwe kupisa.

• Zvizere-otomatiki kudzora mabasa

Iyo control system (AI, V5.0) inoratidzwa nemabasa ane simba uye akazara, senge kiyi imwe yekutanga kumusoro / kudzima, nguva yekubatidza / kudzima, yakakura kuchengetedza kuchengetedza system, akawanda otomatiki kugadzirisa, kuvharika kwehurongwa, nyanzvi system, muchina wevanhu. nhaurirano (mitauro yakawanda), kuvaka otomatiki interfaces, nezvimwe.

• Complete unit abnormality self-diagnosis uye kudzivirira basa

Iyo control system (AI, V5.0) inoratidza 34 abnormality yekuzviongorora uye mabasa ekudzivirira.Matanho otomatiki anozotorwa nesystem zvinoenderana nedanho rekukanganisa.Izvi zvinoitirwa kudzivirira tsaona, kudzikisira basa revanhu uye inovimbisa kushanda kwakasimba, kwakachengeteka uye kwakagadzikana kwechiller.

• Unique mutoro kugadzirisa basa

Iyo yekudzora sisitimu (AI, V5.0) ine yakasarudzika mutoro wekugadzirisa basa, iyo inogonesa kugadzirisa otomatiki kwekubuda kwechiller zvinoenderana nemutoro chaiwo.Iri basa haringobatsiri kudzikisa nguva yekutanga / kuvharwa uye nguva yekunyungudutsa, asi zvakare rinobatsira kuita kushoma kushanda uye kushandiswa kwesimba.

• Unique mhinduro kutenderera vhoriyamu kudzora tekinoroji

Iyo control system (AI, V5.0) inoshandisa tekinoroji yeternary control tekinoroji kugadzirisa vhoriyamu yekutenderera kwemhinduro.Sechinyakare, chete maparamita ejenareta fluid level anoshandiswa kudzora vhoriyamu yekutenderera kwemhinduro.Iyi tekinoroji nyowani inosanganisa kwakakodzera kwekumisikidza & tembiricha yeyakagadziriswa mhinduro uye nhanho yemvura mujenareta.Zvichakadaro, yakakwira frequency-variable control tekinoroji inoiswa kune mhinduro pombi kugonesa unit kuwana yakakwana yakatenderedzwa mhinduro vhoriyamu.Iyi tekinoroji inovandudza kushanda zvakanaka uye inoderedza nguva yekutanga uye kushandiswa kwesimba.

• Kugadzirisa kugadzirisa kugadzirisa teknolojia

Iyo yekudzora sisitimu (AI, V5.0) inoshandisa yakasarudzika yekudzora tekinoroji kugonesa chaiyo-nguva yekutarisa / kudzora kwekutarisa uye huwandu hweiyo concentrated solution pamwe nehuwandu hwemvura inopisa.Iyi sisitimu inogona kuchengetedza chiller pasi yakachengeteka uye yakagadzikana pakakwirira-concentration mamiriro, kuvandudza chiller kushanda zvakanaka uye kudzivirira crystallization.

• Intelligent otomatiki mhepo yekuchenesa basa

Iyo yekudzora sisitimu (AI, V5.0) inogona kuona chaiyo-nguva yekutarisisa yevacuum mamiriro uye kubvisa iyo isinga-condensable mweya otomatiki.

• Unique dilution stop control

Iyi yekudzora sisitimu (AI, V5.0) inogona kudzora nguva yekushanda yemapombi akasiyana anodiwa kuti dilution ishande zvinoenderana neiyo concentrated solution concentration, ambient tembiricha uye yakasara yefiriji mvura vhoriyamu.Naizvozvo, iyo yakakwana yekuisa inogona kuchengetedzwa kune chiller mushure mekuvhara.Crystallization inovharirwa uye chiller rekutanga nguva inopfupikiswa.

• Kushanda parameter utariri hurongwa

Kuburikidza neinterface yeiyi control system (AI, V5.0), mushandisi anogona kuita chero anotevera mashandiro kune gumi nemaviri akakosha paramita ane chekuita nekuchiller kuita: chaiyo-nguva kuratidza, kugadzirisa, kuseta.Zvinyorwa zvinogona kuchengetwa kuitira zviitiko zvezvakaitika kare.

• Unit fault management system

Kana chero kukurumidza kwekukanganisa kunoratidzwa pane yekushanda interface, iyi yekudzora sisitimu (AI, V5.0) inogona kutsvaga uye kutsanangura kukanganisa, kupa mhinduro kana dambudziko rekupfura kutungamira.Kurongeka uye kuongororwa kwenhamba kwezvikanganiso zvekare zvinogona kuitwa kuti zvifambise basa rekuchengetedza rinopihwa nevashandisi.