Products

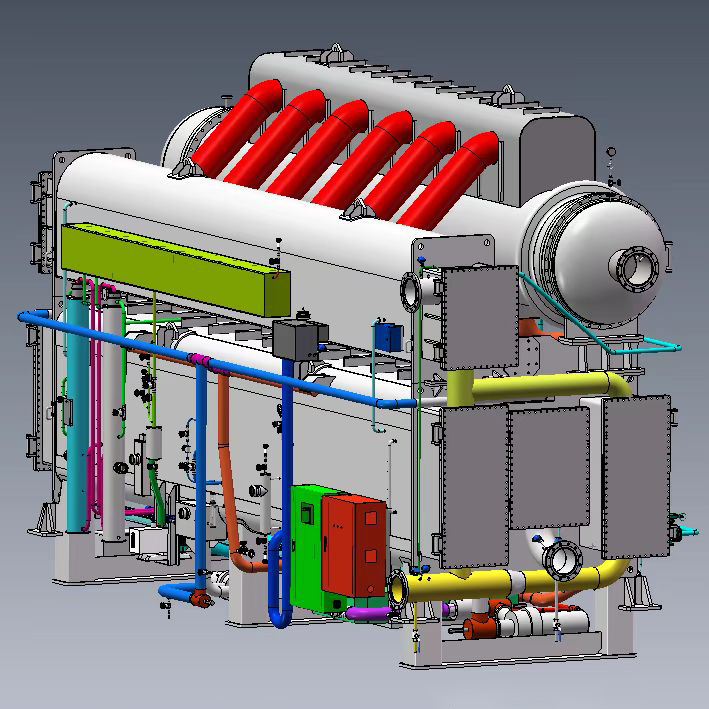

Steam Absorption Heat Pump

LiBr absorption kupisa pombi zviri nyore kushanda uye kuchengetedza.

Iyo otomatiki mweya yekuchenesa sisitimu inovimbisa kuti iyo yakachipa yehutsi yekunyudza kupisa pombi inogara ichimhanya, zvichiita kuti ive sarudzo yakakwana yekurasa kupisa kudzoreredza kunoda chiitiko chisina kunetseka.Uyezve, kuvakwa kwepombi yekupisa inochengetedza kuti inokwanisa kumira nekuoma kwekushandiswa kwenguva refu, zvichiita kuti ive mari yakanaka kune mabhizinesi ari kutsvaga mhinduro inodhura.

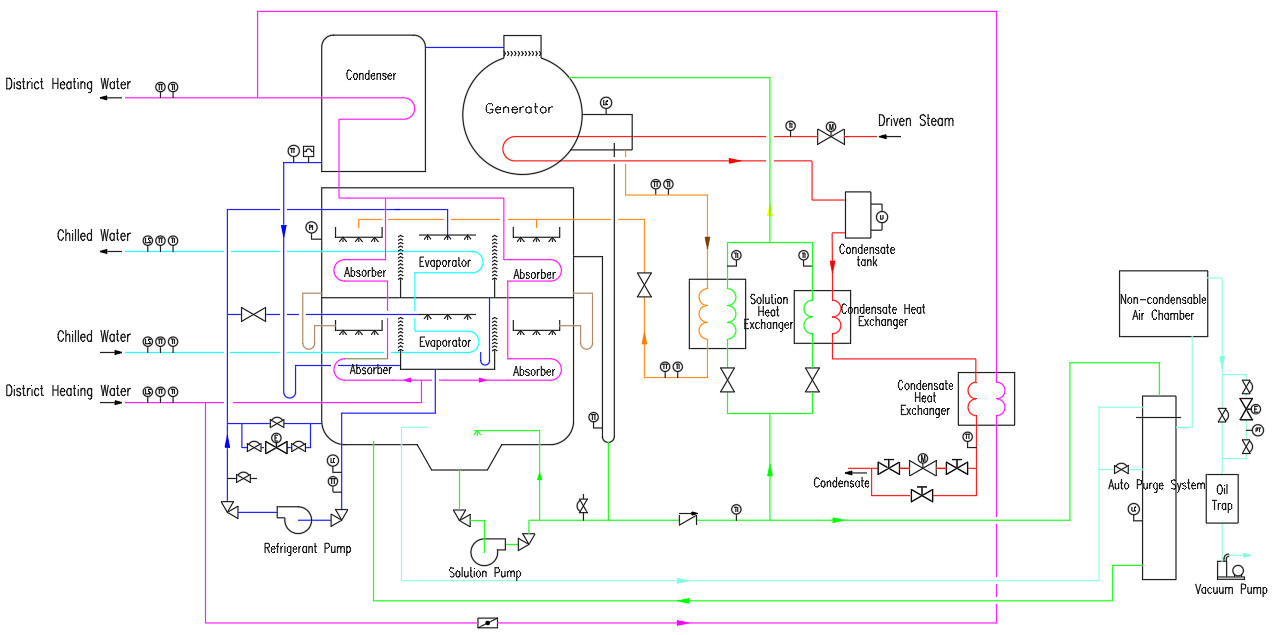

Kuita kwakanakisa kwepombi yekupisa inodhura yakachipa inobva kune yakasarudzika kushanda musimboti.Kupisa kwetsvina kunodzoserwa muevaporator, muitiro unosanganisira kubuda kwemvura yefiriji kubva pamusoro pemachubhu ekupisa.Iyo refrigerant vapor inogadzirwa muevaporator inotorwa neyakaomeswa mhinduro mumudziyo, uye kupisa kunopisa kunopisa mvura inopisa kusvika kune tembiricha yepamusoro kuti iwane inodiwa yekupisa.Iyo pombi yekupisa yakashongedzerwa nehunyanzvi hwemazuva ano, kuve nechokwadi chekuti inogara ichishanda nekunyatsogona.

Iyo dhizaini yekupisa yekupisa ndeyekuona kuti yakanyungudutswa lithium bromide mhinduro inopisa kusvika kune yakakwira tembiricha, uye yozotumirwa kune jenareta, uko inopiswa neinopisa sosi kuti ibudise refrigerant vapor, iyo inodzosera zvakananga mvura inopisa mukati. condenser kune tembiricha yepamusoro.

Mukupedzisa, lithium bromide absorption heat pumps inzira dzine simba kune echinyakare kudziyisa uye kutonhora masisitimu maererano nekukanganisa kwezvakatipoteredza, kuita uye mutengo-kubudirira.Chishandiso ichi chinosiyanisa bhizinesi rako seyakazvipira kushandiswa kwesimba kwakasimba.

Kuti ushandise zvizere kupisa kwakasara kwemvura inopisa, iyo evaporator uye inonyudza inogadzirwa senge kumusoro uye nechepasi zvikamu, kuitira kuti kusungirirwa kwemhinduro yakanyungudutswa pakubuda kweiyo absorber kuderedzwa uye mutsauko wepakati pakati pe kupinza uye kubuda kwejenareta kunowedzerwa, pakupedzisira kunonatsiridza mashandiro eiyi yakachipa yekunyudza kupisa pombi.

1.Jenareta

Jenareta basa: Jenareta ndiyo inopa simba reiyi Libr absorption kupisa pombi.Iyo inofambiswa inopisa sosi inopinda mujenareta uye inopisa iyo yakanyungudutswa LiBr mhinduro.Mvura iri mumushonga yakanyungudutswa inoputika semhute yefiriji uye inopinda mucondenser.Zvichakadaro, iyo dilute solution inonamirwa mune yakagadziriswa mhinduro.

Jenareta igoko-uye-chubhu chimiro chinosanganisira kupisa kwekutamisa chubhu, chubhu ndiro, ndiro yekutsigira, goko, bhokisi remhepo, kamuri yemvura uye baffle ndiro.Semudziyo wepamusoro-soro mukati mepombi yekupisa system, jenareta ine vacuum yemukati inenge zero (micro negative pressure).

2. Condenser

Basa re condenser: Refrigerant vapor kubva mujenereta inopinda mu condenser uye inopisa mvura inopisa kusvika kune yakakwirira tembiricha.Mhedzisiro yekupisa inobva yawanikwa.Mushure mokunge mupfuti wefiriji wapisa mvura inopisa, inopindirana nenzira yefiriji yefiriji uye inopinda mu evaporator.

Iyo condenser, inova ganda-uye-tubhu chimiro, ine kupisa kwekutamisa chubhu, chubhu ndiro, ndiro yekutsigira, goko, tangi remvura uye kamuri yemvura.Kazhinji, condenser uye jenareta zvakabatanidzwa zvakananga nemapombi, kuitira kuti ivo vari kunyanya pakumanikidzwa kwakafanana.

3. Evaporator

Basa reiyo evaporator: Iyo evaporator imarara kupisa kudzoreredza unit.Mvura yefiriji kubva mucondenser inoputika kubva pamusoro pechubhu yekutamisa kupisa, ichibvisa kupisa kubva muCHW mukati mechubhu nekuitonhodza.Refrigerant vapor inoputika kubva pamusoro pechubhu yekupisa inopisa inopinda mumudziyo.

Iyo evaporator inovakwa seganda-uye-chubhu chimiro uye inosanganisira kupisa kwekutamisa chubhu, chubhu ndiro, ndiro yekutsigira, goko, baffle ndiro, tray yekupfapfaidza uye imba yemvura.Kumanikidza kwekushanda kweiyo evaporator inenge 1/10 yemagetsi ejenareta.

4. Mubati

Absorber basa: Iyo inopinza inhengo inogadzira kupisa.Refrigerant vapor kubva kune evaporator inopinda mumudziyo umo inotorwa neyakagadziriswa mhinduro.Mushonga wakakoshwa unoshandurwa kuita mushonga wakanyungudutswa uyo unopomba kudenderedzwa rinotevera.Sezvo mhute yefiriji inobatwa nemushonga wakaiswa, huwandu hwakawanda hwekupisa hunogadzirwa hunogadzirwa, hunopisa mvura inopisa kusvika kune yakakwirira.Iyi ndiyo nzira yekupisa kunowanikwa.

Iyo inopinza inovakwa seganda-uye-tubhu chimiro uye ine kupisa kwekutamisa chubhu, chubhu ndiro, tsigiro ndiro, shell, purging system, spraying plate nekamuri yemvura.Iyo inopinza ndiyo yakaderera kudzvinyirira mudziyo mumhepo inopisa yepombi uye iri pasi pesimba guru remhepo isina-condensable.

5. Heat exchanger

Heat exchanger function: The heat exchanger itsvimbo yekudzoreredza kupisa unit inoshandiswa kudzoreredza kupisa muLiBr mhinduro.Kupisa mukati mekugadzirisa kwakagadziriswa kunotamirwa kune yakasvibiswa sarudzo nemudziyo wekupisa kuti uvandudze kushanda kwekushisa.

Nechigadziro cheplate, iyo inopisa inopisa ine yakakwirira yekupisa uye inoshamisa simba rekuchengetedza simba.

6. Automatic air purge system

Sisitimu basa: Iyo air purge system yakagadzirira kupomba kunze iyo isinga-condensable mweya mune ino yakachipa Libr absorption yekupisa pombi uye kuchengetedza yakakwira vacuum mamiriro.Munguva yekushanda, iyo yakanyungudutswa mhinduro inoyerera nekumhanya kukuru kugadzira yemunharaunda yakaderera yekumanikidza zone yakatenderedza muromo wekuburitsa.Mhepo isina-condensable saka inoputirwa kunze kwepombi inopisa.Iyo sisitimu inoshanda mukuwirirana nepombi yekupisa.Ipo pombi yekupisa iri kushanda, iyo otomatiki sisitimu inobatsira kuchengetedza yakakwira yemukati vacuum, shuwa mashandiro ehurongwa uye kuwedzera hupenyu hwesevhisi.

Iyo air purge system ine ejector, inotonhorera, mafuta musungo, silinda yemhepo uye mavharuvhu.

7. Pombi yekugadzirisa

Iyo pombi yemhinduro inoshandiswa kuendesa mhinduro yeLiBr uye kuve nechokwadi chekuyerera kwemvura inoshanda mukati mepombi yekupisa.

Iyo pombi yemhinduro ipombi yakavharirwa zvakakwana yecentrifugal ine zero fluid leakage, yakaderera ruzha, yakakwirira kuputika humbowo kuita, kushoma kugadzirisa uye hupenyu hurefu.

8. Refrigerant Pombi

Iyo pombi yefiriji inoshandiswa kufambisa mvura yefiriji uye kuve nechokwadi chekupfapfaidza kwemvura yefiriji pane evaporator heat exchange chubhu.

Iyo pombi yefiriji ipombi yakavharirwa zvizere yemumagaba isina kubuda kwemvura, ruzha rwakadzika, kuputika kwehumbowo hwepamusoro, kugadzirisa kushoma uye hupenyu hurefu hwesevhisi.

9. Vacuum Pombi

Iyo pombi yevacuum inoshandiswa pakutsvaira panguva yekutanga-kumusoro uye kuchenesa mweya panguva yekushanda.

Pombi yevacuum ine rotary vane impeller.Kiyi pakuita kwayo ndeye vacuum mafuta manejimendi.Kudzivirira emulsification yemafuta kune mhedzisiro yakanaka pamhepo yekuchenesa kuita uye inobatsira kuwedzera hupenyu hwebasa.

10. Magetsi cabinet

Senzvimbo yekudzora yeLiBr yekupisa pombi, iyo kabati yemagetsi inogara iyo huru yekutonga uye zvikamu zvemagetsi.

- Waste Heat Recovery.Kuchengetedza Kwesimba & Kuderedzwa kweEmission

Inogona kushandiswa kudzoreredza LT tsvina inopisa mvura kana LP chiutsi mumagetsi ekupisa, kuchera mafuta, petrochemical munda, simbi engineering, makemikari kugadzirisa munda, etc. Inogona kushandisa mvura yerwizi, pasi pevhu kana imwe yakasikwa mvura sosi kushandura LT mvura inopisa. mumvura inopisa yeHT nechinangwa chekudziya kwedunhu kana kupisa.

- Dual mhedzisiro (inoshandiswa kutonhora / kupisa)

Inotyairwa negasi rechisikigo kana chiutsi, iyo mbiri mhedzisiro yekupinza kupisa pombi inogona kudzoreredza kupisa kwemarara nekunyanya kushanda nesimba (COP inogona kusvika 2.4).Iyo inoshongedzerwa nezvose zviri zviviri kupisa uye kutonhora basa, kunyanya inoshanda kune panguva imwe chete yekudziya / kutonhora kudiwa.

- Maviri-chikamu kutorwa & yakakwirira tembiricha

Kirasi II Maviri-chikamu absorption yekupisa pombi inogona kusimudza tembiricha yemvura yakaraswa kusvika pa80°C pasina kumwe kupisa.

-Kudzora kwakangwara &Kushanda kuri nyore

Yakazara otomatiki kudzora, inogona kuona imwe-bhatani pa/kudzima, kudzora mutoro, mhinduro yekutarisa muganho kudzora uye kure kutarisa.

- Zvizere otomatiki kudzora mabasa

Iyo control system (AI, V5.0) inoratidzwa nemabasa ane simba uye akazara, akadai se-bhatani rimwe kutanga / kumira, timer on / off, advanced kuchengetedza kuchengetedza system, akawanda otomatiki kugadzirisa, system interlock, nyanzvi system, munhu-muchina. nhaurirano (mitauro yakawanda), kuvaka otomatiki interfaces, nezvimwe.

-Yakazara unit abnormality self-diagnosis uye kudzivirira basa

Iyo control system (AI, V5.0) ine 34 abnormality yekuzviongorora uye mabasa ekudzivirira.Zvichienderana nehuwandu hwekusagadzikana, system yacho inotora chiito.Izvi zvakagadzirirwa kudzivirira tsaona, kuderedza kushanda kwevanhu uye kuona kuenderera, kwakachengeteka uye kwakagadzikana kushanda kwechiller.

-Unique mutoro kugadzirisa basa

Iyo yekudzora sisitimu (AI, V5.0) ine yakasarudzika mitoro yekugadzirisa basa, iyo inobvumira absorption kupisa pombi unit kubuda kuti igadziriswe otomatiki zvichienderana nemutoro chaiwo.Iri basa haringobatsiri kudzikisira nguva yekutanga / yekuvhara uye nguva yekunyungudutsa, asi zvakare inobatsira kuderedzwa kwekuita nguva uye kushandiswa kwesimba.

-Unique Solution Kutenderera Kudzora Tekinoroji

Iyo control system (AI, V5.0) inoshandisa tekinoroji ternary control tekinoroji kugadzirisa mhinduro yekutenderera kwevhoriyamu.Nechinyakare, chete jenareta yemvura level paramita inoshandiswa kudzora mhinduro kudzokorodza vhoriyamu.Iyi tekinoroji nyowani inosanganisa zvakanakira yekuisa & tembiricha yeyakagadziriswa mhinduro uye nhanho yemvura mujenareta.Zvichakadaro, yepamberi frequency variable control tekinoroji inoiswa kune pombi yekugadzirisa kuitira kuti iyo unit iwane yakakwana yakatenderedzwa mhinduro vhoriyamu.Iyi tekinoroji inovandudza kushanda zvakanaka uye inoderedza kutanga-up nguva uye kushandiswa kwesimba.

- Solution Concentration Control Technology

Iyo control system (AI, V5.0) inoshandisa yakasarudzika yekudzora tekinoroji kugonesa chaiyo-nguva yekutarisa / kutonga kweiyo yekumisikidza uye vhoriyamu yeyakagadziriswa mhinduro uye vhoriyamu yemvura inopisa.Iyi sisitimu inogona kuchengetedza kupisa pombi pasi peyakachengeteka uye yakagadzikana yakakwirira yekumisikidza mamiriro, kunatsiridza kushanda zvakanaka uye kudzivirira crystallization.

- Intelligent otomatiki mhepo yekuchenesa basa

Iyo yekudzora sisitimu (AI, V5.0) inogona kuona chaiyo-nguva yekutarisa yevacuum mamiriro uye otomatiki kuchenesa iyo isinga-condensable mhepo.

- Yakasarudzika dilution yekumisa kudzora

Iyi control system (AI, V5.0) inogona kudzora nguva yekumhanya yemapombi ekugadzirisa anodiwa kuti dilution ishande zvinoenderana nekusangana kweiyo concentrated solution, ambient tembiricha uye huwandu hwasara hwemvura mufiriji.Izvi zvinobvumira optimum concentration kuti ichengetedzwe kune chiller mushure mekuvhara.Crystallization inodzivirirwa uye kupisa pombi restart nguva yakaderedzwa.

-Inoshanda parameter manejimendi system

Kuburikidza nekusangana kweiyi control system (AI, V5.0), mufambisi anogona kuita chero cheanotevera mashandiro e12 yakakosha paramita ine chekuita nekupisa kwepombi kuita: chaiyo-nguva kuratidza, kugadzirisa, kugadzirisa.Zvinyorwa zvinogona kuchengetwa zvezvakaitika kare zvekushanda.

- Unit kukanganisa manejimendi system

Kana imwe nguva kukanganisa ichiratidzwa pane yevashandisi interface, iyi yekudzora sisitimu (AI, V5.0) inogona kutsvaga nekutsanangura iyo kukanganisa, kupa mhinduro kana kugadzirisa dambudziko.Kurongeka uye kuongororwa kwenhamba kwezvikanganiso zvezvakaitika kare zvinogona kuitwa kuti zvive nyore kugadzirisa mashandiro.